Many customer ask about Shell Clad and in particular how it works, how easy it is to use and the benefits and disadvantages of the product. This brief guide explains about Shell Clad. We hope it helps but if you have any questions, please contact us on 01785 818111 and we will be happy to help.

Kind regards, Mark Thompson, Printdesigns Limited

**************************

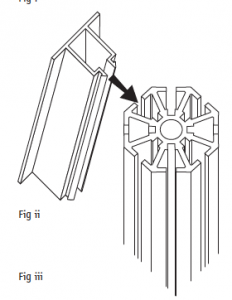

Shell Clad adapters are simple clips that are designed to snap-onto the pillars of exhibition shell schemes.

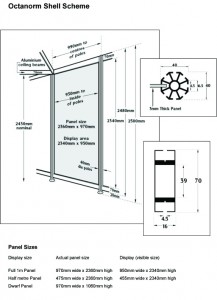

There are a number of exhibition shell schemes in use but most systems work by utlising a series of upright aluminium posts, braced at the top and bottom with horizontal beams. In-between each set of posts and beams is normally an infill panel. These panels can be plain white or sometimes they are covered with a fabric that allows the exhibitor to fix information to them with velcro.

The problem with Shell Schemes is that you do not have a perfectly flat wall to fasten graphics to. This is because the pillars of the shell scheme generally stand proud of the infill panels. The attached picture illustrates an Octanorm Shell Scheme and shows the typical construction.

Given that the backwall is not flat and given that stand contractors and exhibition organisers do not allow for materials to be stuck onto the metal work of the stand, covering the backwall with graphics that fit edge to edge is difficult!

Shell Clad adapters work by snapping on to the pillars of the stand by clicking into the groove of the post. The adapter is essentially an arrow head with a flat face that is covered in velcro. By clipping 3 adapters onto each upright post, you create a vertical velcro covered pillar that graphics can fasten to. As Shell Clad adapters can be removed and re-used without the metalwork of the stand being covered in glue residue, there is no problem using them at events.

With regards to the graphic panels, it is important to note that these have to be made to exacting sizes so they fit between the posts. The base measurement of the panel is the centre to centre post measurement and you can see from the attached illustration that this is 990mm for Octanorm (as is the case with several other systems).

You would be forgiven for assuming that all Shell Clad panels are this size but unfortunately it is a little more complicated than that! Panels that run into the inside corners of the stand (where two walls converge) ate slightly smaller. This is because the adapters stand the clips off the wall by 32mm. Inversely, panels on the outside edge of a stand are usually slightly wider by 21mm which is purely cosmetic so that the panel covers the whole of the shell clad adapter on the outside edge rather than half of it (so you don't see exposed velcro on the outside edge of the stand).

Panels for Shell Clad can be produced onto a number of materials.....

Stoplight polyester, laminated with a crystal film. The panel at around 450 microns is heavy but still flexible and so Shell Clad (who make the clips) recommend backing onto a 4mm fluted PVC sheet called Magi-Clad.

Remember those beach mats that are made of a series of wooden slats? They can be coiled-up like a snake but you cannot compress them on the width? Magi-Clad works in the same way. When bonded to the reverse of the panel, the resultant coil-able snake is rigid on the width but can still be rolled up.

Magi-Clad is a great product as panels sit perfectly flat without having to pull tension across then when hanging the panels. The drawback is that adding magiclad to a standard heavyweight rollable panel adds are £60 to the cost. For this reason many customers do not opt for it. Attached is a picture of an 8M wall we made. These panels were not backed-up with magi-clad and you can see the customer achieved a good finish.

We are actually working on our own version of Magi-Clad now formed from a 5mm material that is V-Cut with a series of slats. We are still in the testing phase but hope to have a workable solution in the coming weeks.

As well as roll panels, Shell Clad panels can be produced onto rigid boards like 5mm foamex or di-bond. Ungainly to transport and difficult to store, these panels are not popular but serve a purpose in that you can fix things like shelves etc to them as they are more structural than rollable materials.

Finally, fabric is becoming an option. Shell Clad call this system Fabri-Clad. The panel is produced as one large sheet and the velcro is sewn in place. The great thing about a one piece fabric panel is that assembly takes less time as there are no panels to join-up. Furthermore there are no visible seams. Attached is a wall we produced last week for a company Gnaw Chocolate. The stand compromised of 3 panels however only one is shown here as tested on our own Shell Scheme in our demo room.

Shell Clad is a great system as it allows continuous mural style graphics along the wall of any shell scheme without wasting valuable floor space. The only downside is that panels have to be produced to fit the stand. It means that is you have several shows throughout the year then planning must be considered to ensure that panels will fit all forthcoming shows. You cannot just buy a series of panels and expect they will fit any stand.

Finally, if you are considering Shell Clad as a solution for decorating your Shell Scheme but you think that the graphics might not be versatile for all events, why not consider Curvorama. Curvorama works by hanging the panels on the beams not the posts of the stand and is flexible for almost any type of Shell Scheme.

You can find videos on Shell Clad and Curvorama on the Printdesigns Youtube page.

Best regards

Mark